In today’s competitive landscape, optimizing your supply chain is crucial. A key aspect of this is ensuring you have qualified, reliable suppliers. But managing supplier qualification can be a time-consuming and error-prone process, especially if you’re relying on spreadsheets.

This blog dives into the age-old debate: software vs spreadsheets for supplier qualification. We’ll explore the limitations of spreadsheets and how dedicated software can streamline the process for maximum efficiency.

The Spreadsheet Struggle

Spreadsheets are familiar and widely available, making them a tempting option for supplier qualification. However, their limitations become apparent as your needs grow:

Data Silos & Errors: Spreadsheets are prone to human error during data entry and manipulation. Scattered files across different departments create data silos, making it difficult to maintain a single source of truth.

Limited Collaboration: Sharing and collaborating on spreadsheets can be cumbersome. Version control issues arise, leading to confusion and potential use of outdated information.

Scalability Issues: As your supplier base expands, spreadsheets quickly become unwieldy. Complex qualification criteria and large datasets are difficult to manage effectively in spreadsheets.

Lack of Automation: Repetitive tasks like sending qualification requests and chasing responses are manual and time-consuming. Spreadsheets offer little to no automation for streamlining the process.

The Software Advantage

Dedicated supplier qualification software offers a powerful alternative:

Centralized Data & Visibility: All supplier data is stored in a central, secure location, ensuring everyone has access to the latest information. Real-time updates eliminate data silos and improve decision-making.

Streamlined Collaboration: User-friendly interfaces facilitate collaboration. Team members can easily share documents, track progress, and communicate effectively.

Scalability & Flexibility: The software can accommodate a growing supplier base and complex qualification criteria. Flexible workflows can be customized to your specific needs.

Automated Workflows: Eliminate manual tasks by automating qualification requests, reminders, and document collection. This frees up time for strategic analysis and supplier relationship management.

Advanced Analytics & Reporting: Gain valuable insights from supplier data. Generate reports on key performance indicators (KPIs) to identify trends and make data-driven decisions.

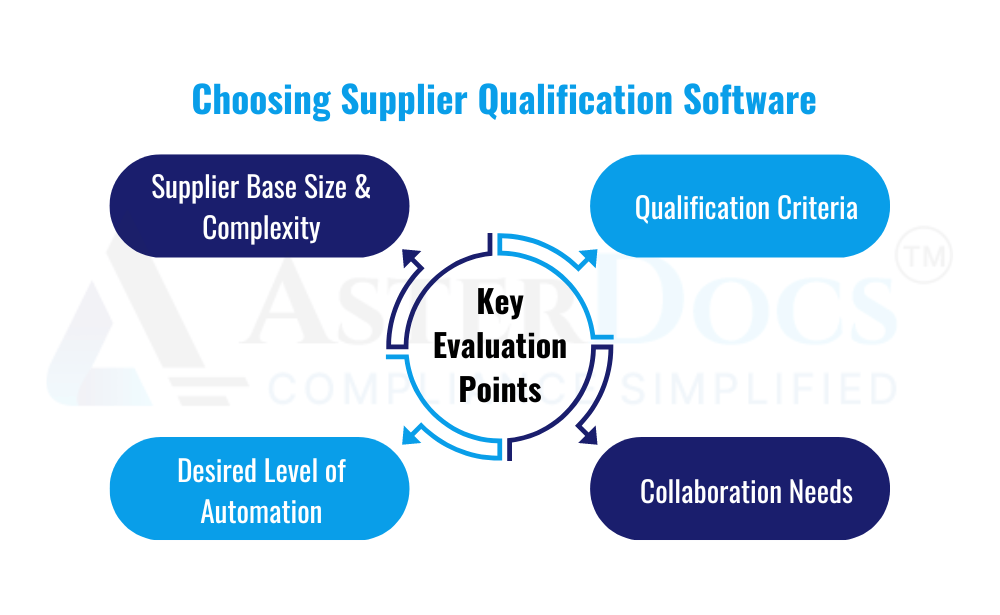

Choosing the Right Path

Spreadsheets might work for a very small supplier base with basic qualification criteria. But for most businesses, dedicated software offers significant advantages. Consider these factors when making your decision:

Supplier Base Size & Complexity: A larger and more complex supplier base necessitates software for efficient management.

Qualification Criteria: If your qualification process involves multiple factors and documents, software streamlines data capture and analysis.

Desired Level of Automation: Software automates tasks, freeing up valuable time for strategic work.

Collaboration Needs: Software facilitates collaboration across teams and departments.

Conclusion

Streamlining your supplier qualification process is essential for a robust supply chain. While spreadsheets might seem like a familiar option, dedicated software offers a clear path to efficiency and improved decision-making. By leveraging the power of software, you can ensure you have the right suppliers in place to optimize your business for success.