Maintaining compliance and ensuring product safety are not just priorities but also essentials given the high stakes and small margin for error. As industry leaders strive to meet stringent regulations and consumer expectations, document traceability software for food manufacturing emerges as a critical tool in their arsenal. This software is not just about tracking documents; it’s about building a transparent, efficient, and reliable food production process.

But why is traceability software a necessity?

Let us look at the main reasons why it is important for the food manufacturing industry.

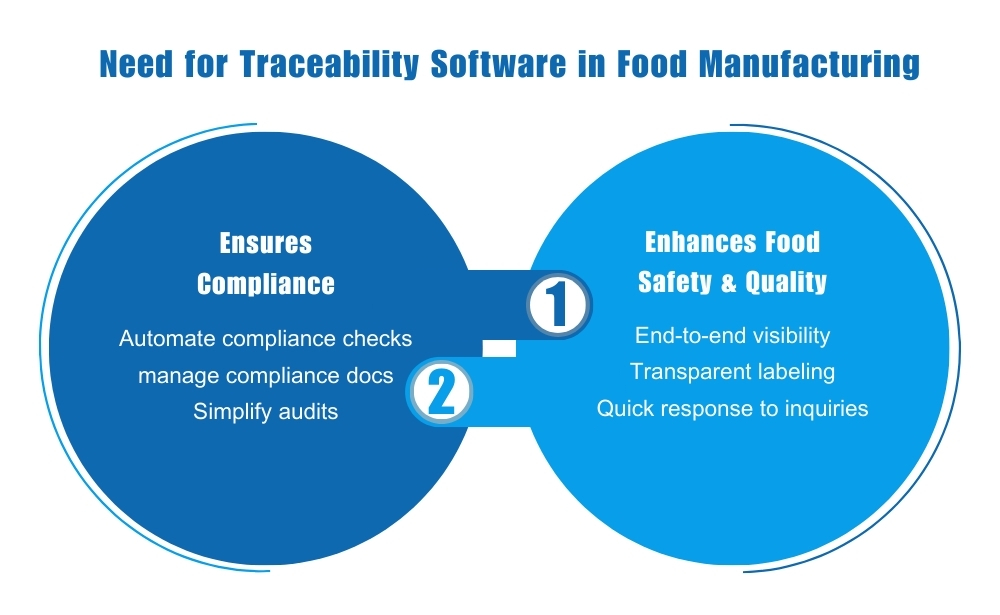

1. Ensuring Compliance with Regulations

One of the most significant challenges in food manufacturing is staying compliant with ever-evolving regulations. Governments and regulatory bodies around the world are strengthening their food safety standards, and non-compliance can lead to severe penalties, product recalls, and even damage to a brand’s reputation.

Traceability software for food manufacturing helps companies:

- Track and manage compliance documents: Whether it’s certifications, inspection reports, or supplier documents, the software ensures that all critical documentation is stored, updated, and easily accessible.

- Automate compliance checks: The software can automatically flag any missing or outdated documents, ensuring that compliance requirements are met at all times.

- Simplify audits: During an audit, having all relevant documents organized and traceable can significantly reduce the time and stress involved.

2. Enhancing Food Safety and Quality Control

Food safety is at the core of any food manufacturing business. Consumers expect the products they purchase to be safe and of high quality.

Document traceability software plays a crucial role in enhancing food safety by:

- Providing end-to-end visibility: From raw materials to the finished product, the software tracks every step in the production process, ensuring that any issues can be quickly identified and addressed.

- Reducing the risk of contamination: With detailed tracking and real-time updates, the software minimizes the chances of cross-contamination and ensures that food safety protocols are followed.

- Supporting quality control initiatives: By tracking quality control documents and procedures, the software helps maintain consistent product quality, which is essential for consumer trust and brand loyalty.

3. Streamlining Operations and Increasing Efficiency

Document traceability software can streamline operations in several ways:

- Reducing manual errors: By automating the tracking and management of documents, the software reduces the likelihood of human error, which can lead to costly mistakes.

- Speeding up the decision-making process: With all necessary documents and data available at the click of a button, decision-makers can act quickly and confidently.

- Improving collaboration: The software allows different departments, such as quality control, compliance, and production, to collaborate more effectively by sharing access to critical documents and data.

4. Building Consumer Trust through Transparency

In an age where consumers are increasingly concerned about where their food comes from and how it’s made, transparency is more important than ever.

Document traceability software helps build consumer trust by:

- Providing traceability from farm to fork: Consumers can trace the journey of their food, from the source of the raw materials to the final product on store shelves.

- Enabling transparency in labeling: The software ensures that all claims made on labels, such as “Organic” or “Halal,” are backed by the necessary documentation.

- Responding quickly to consumer inquiries: In case of a product issue or recall, the software allows companies to quickly trace the problem and provide consumers with accurate information.

5. Supporting Sustainability and Ethical Sourcing

Sustainability is no longer a trend; it’s a necessity. Consumers and regulators alike are demanding that food manufacturers operate sustainably and ethically.

Document traceability software supports these efforts by:

- Tracking sustainable sourcing: The software ensures that raw materials are sourced sustainably and ethically, with the necessary documentation to prove it.

- Reducing waste: By optimizing production processes and reducing errors, the software helps minimize waste, contributing to a more sustainable operation.

- Promoting ethical practices: The software tracks and verifies that suppliers adhere to ethical standards, such as fair labor practices and environmental governance.

Conclusion

Document traceability software for food manufacturing is no longer a luxury; it’s a necessity for industry leaders who want to stay competitive, compliant, and trustworthy. As the food industry continues to evolve, the need for robust traceability solutions will only grow. Industry leaders who embrace this technology now will be better positioned to meet future challenges and opportunities.

If you’re a food manufacturer looking to stay ahead of the curve, investing in AsterDocs is a step you can’t afford to miss. AsterDocs’ document traceability feature ensures compliance, enhances food safety, and builds consumer trust while supporting your sustainability goals. Visit now and invest in the right technology!