The nutraceutical industry is subject to strict regulations and constantly shifting quality standards. Businesses must manage complex supply chains, from sourcing raw materials to delivering finished products. As these operations grow, so do the risks associated with compliance, supplier management, and ensuring product quality. That’s where a supply chain scorecard comes into play.

A supplier scorecard is more than just a performance tracker; it’s a tool for assessing and improving every aspect of your supply chain. By turning data into actionable insights, businesses can move from a position of risk to reliability.

What is a Supply Chain Scorecard?

A scorecard is a structured tool used to evaluate the performance of a company’s supply chain. It tracks key metrics such as:

- Supplier reliability

- Cost efficiency

- Risk management

- Compliance with industry standards

- Product quality control

By using a scorecard, businesses gain a holistic view of their operations, identifying areas that need improvement while reinforcing strengths.

Why the Nutraceutical Industry Needs a Supply Chain Scorecard

In the nutraceutical sector, maintaining a smooth and reliable supply chain is crucial. The nature of these products, combined with the demand for transparency and safety, makes managing supply chains more complex. Here are the key reasons why nutraceutical companies should use a supply chain scorecard:

- Compliance with Regulatory Standards

Nutraceutical companies are held to strict regulations by bodies like the FDA and EFSA. A scorecard helps track compliance at every stage—ensuring that suppliers meet safety standards, certifications are up-to-date, and products are properly tested for quality. - Improved Supplier Performance

The scorecard provides visibility into supplier performance, allowing businesses to measure on-time delivery, quality of raw materials, and adherence to agreements. By identifying underperforming suppliers, businesses can take proactive steps to resolve issues before they escalate into costly problems. - Risk Mitigation

Supply chains are vulnerable to risks such as disruptions, shortages, or changes in regulatory requirements. A scorecard allows companies to foresee and manage these risks, ensuring a quick response to minimize impact on operations. - Cost Control

Tracking cost-efficiency through a scorecard enables businesses to identify areas where they may be overspending, whether on logistics, suppliers, or raw materials. This data-driven approach leads to better resource allocation, ultimately reducing operational costs. - Quality Control Across the Supply Chain

Ensuring product quality is essential, especially for nutraceuticals, where any compromise in quality could lead to severe legal and financial repercussions. A scorecard provides checkpoints to assess the quality of raw materials, packaging, and the finished product, helping companies catch issues early.

How Supply Chain Scorecards Improve Operational Efficiency

Using a supplier scorecard transforms the way businesses manage their operations. By evaluating performance metrics across suppliers, processes, and logistics, companies can build more reliable supply chains. Here’s how the scorecard enhances operational efficiency:

- Enhanced Decision-Making

Data is at the core of a supplier scorecard. With up-to-date metrics on cost, performance, and risk, companies can make informed decisions that benefit the entire supply chain, from suppliers to end customers. - Supply Chain Transparency

Nutraceutical companies are often asked to provide transparency across the supply chain, not just for regulatory bodies but also for consumers. The scorecard offers a clear overview of the entire chain, improving accountability and transparency at every level. - Supplier Accountability

When suppliers know their performance is being tracked, they’re more likely to adhere to agreed-upon standards and timelines. This not only improves their performance but also fosters better relationships between nutraceutical companies and their suppliers. - Proactive Risk Management

By using a scorecard, risks are identified early and managed proactively. Whether it’s a delay in raw material supply or a failure to meet regulatory requirements, the scorecard alerts businesses to potential disruptions before they become critical.

Key Metrics to Include in a Scorecard

A supply chain scorecard can track a variety of metrics, but some key areas to focus on in the nutraceutical industry include:

- Supplier On-Time Delivery Rate

Measuring how consistently suppliers deliver on time ensures a steady flow of raw materials without production delays. - Compliance Rate

This tracks how often your suppliers meet regulatory requirements. Ensuring supplier compliance is vital for maintaining industry certifications and avoiding legal issues. - Product Defect Rate

By tracking the number of defects found during quality control, businesses can identify whether issues stem from poor supplier quality or internal processes. - Cost per Unit

Tracking the cost of materials per unit produced helps companies manage their pricing strategy and find opportunities to improve cost efficiency. - Lead Time Variability

This tracks how consistent suppliers are with delivery lead times. A high variability can disrupt production schedules and lead to stockouts or delays.

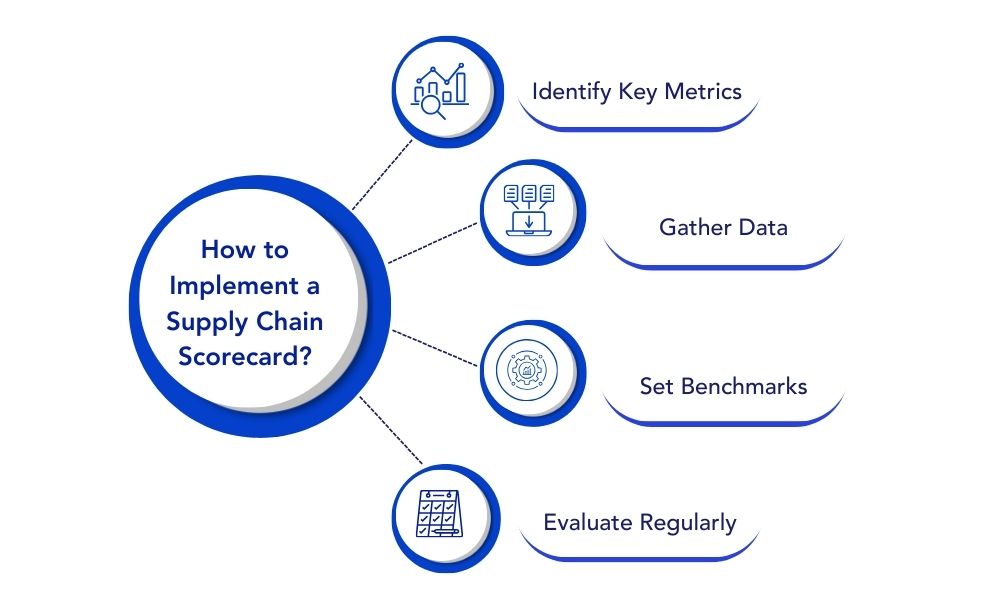

How to Implement a Supply Chain Scorecard for Nutraceutical Operations

Implementing a scorecard requires a structured approach:

- Identify Key Metrics

The first step is deciding which metrics are most critical to your operations, such as supplier reliability, cost efficiency, or regulatory compliance. - Gather Data

Ensure that your systems can track and provide data for each metric. This may involve integrating software platforms or working with suppliers to share performance data. - Set Benchmarks

Establish performance benchmarks that suppliers and internal teams should meet. This sets the foundation for evaluating success. - Evaluate Regularly

Continuously evaluate the scorecard to ensure it reflects the current state of your supply chain. Adjust metrics as needed to adapt to new risks or operational changes.

Conclusion

A supply chain scorecard offers an efficient way to manage the potential risks of the nutraceutical industry’s supply chain. By tracking key metrics like compliance, supplier performance, and risk, nutraceutical companies can shift from reactive to proactive management—ensuring they stay ahead of challenges and maintain a competitive edge.

If you’re ready to strengthen your supply chain through data-driven insights, explore how AsterDocs can help you integrate the right tools for success.