Did you know that a whopping 82% of organizations have experienced a supply chain disruption in the past three years? A variety of factors can cause these disruptions, but one often overlooked culprit is outdated supplier qualification practices.

Many businesses still rely on spreadsheets to track supplier information and qualifications. While spreadsheets might seem like a simple and familiar solution, they can leave your organization exposed to significant risks in today’s ever-evolving regulatory landscape.

The Growing Challenge of Compliance:

Compliance regulations are becoming increasingly complex, with new requirements emerging all the time. Keeping track of these changes and ensuring your suppliers meet them can be a daunting task. Spreadsheets, unfortunately, are not up to the challenge.

Here’s Why Spreadsheets Fall Short:

- Limited Audit Trails: Spreadsheets often lack robust audit trails, making it difficult to track changes made to supplier information. This can be a major issue during audits, where regulators need to see a clear history of your due diligence process.

- Version Control Woes: Multiple versions of the same spreadsheet can easily float around, leading to confusion and inconsistencies. You might unknowingly be making decisions based on outdated information.

- Data Integrity Concerns: Spreadsheets are prone to human error. Data can be easily entered incorrectly or accidentally deleted, jeopardizing the integrity of your supplier qualification process.

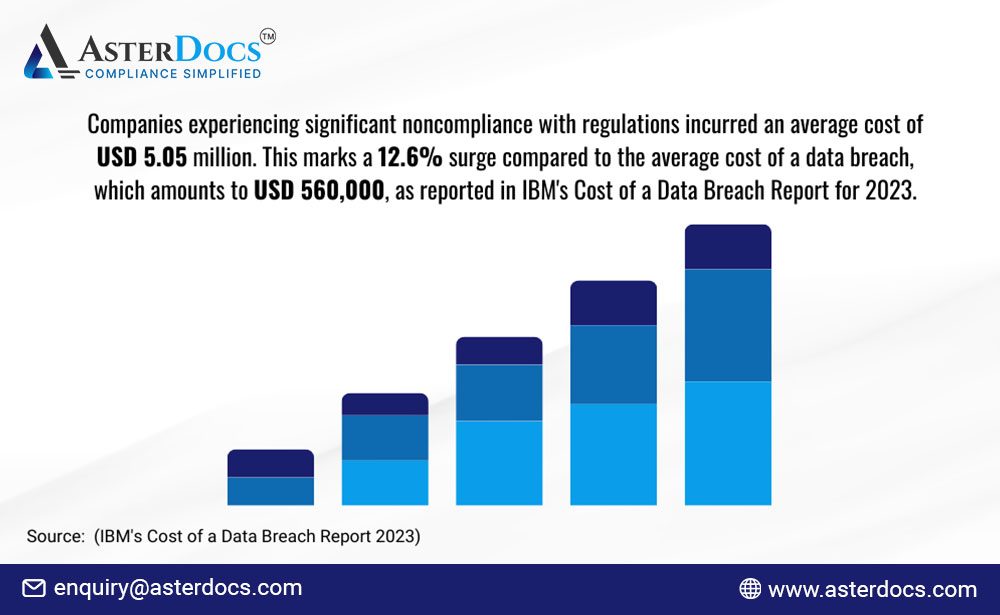

The High Cost of Non-Compliance:

The consequences of non-compliance with supplier qualification regulations can be severe:

- Financial Penalties: Regulatory bodies can impose hefty fines for non-compliance. These fines can eat significantly into your profits.

- Reputational Damage: A public supplier-related incident can damage your brand reputation and customer trust.

- Supply Chain Disruptions: Non-compliant suppliers can cause delays and disruptions in your supply chain, impacting your ability to meet customer demands.

Moving Beyond Spreadsheets:

There’s a better way. Investing in dedicated Supplier Relationship Management (SRM) software can help you overcome the limitations of spreadsheets and ensure a robust, compliant supplier qualification process.

SRM software offers features like:

- Automated Workflows: Streamline the supplier qualification process with automated workflows.

- Version Control: Ensure you’re always working with the latest version of supplier data.

- Audit Trail Tracking: Maintain a clear audit trail of all changes made to supplier information.

- Centralized Data Management: Store all supplier information in a single, secure location.

By moving beyond spreadsheets and embracing dedicated SRM software, you can reduce your risk of non-compliance, protect your reputation, and ensure a smooth-running supply chain. Don’t let outdated practices leave your organization exposed.

To learn how AsterDocs automates and streamlines the end-to-end compliance process so you can save time getting and staying compliant, schedule a demo.