In the world of nutraceuticals – those supplements that bridge the gap between food and medicine – quality is paramount. Consumers trust these products to deliver health benefits, and ensuring that trust starts with selecting the right suppliers. This is where stringent supplier qualification criteria come into play. It acts as the cornerstone for delivering high-quality nutraceuticals from source to shelf.

Why Stringent Criteria Matter

Nutraceutical products often involve complex supply chains, with ingredients sourced from various locations and undergoing multiple processing steps. Without rigorous supplier qualification, there’s a risk of compromising the final product’s quality in several ways:

- Contamination: Contaminants can enter the supply chain at any point, from the source of the raw materials to improper processing at a supplier facility. This can pose serious health risks to consumers.

- Adulteration: Substituting cheaper ingredients or adding unauthorized substances can not only compromise the efficacy of a nutraceutical but also introduce unexpected health risks.

- Inconsistent Quality: Variations in raw materials or processing methods at the supplier level can lead to inconsistencies in the final product. It also impacts its effectiveness and safety.

Stringent Criteria: Building a Quality Firewall

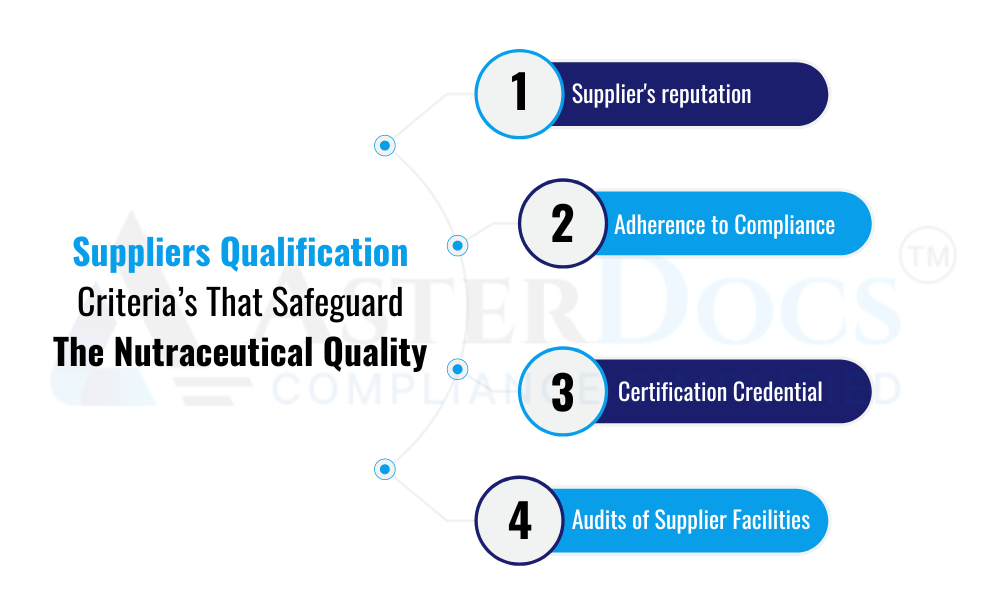

By implementing stringent supplier qualification criteria, nutraceutical companies can build a powerful quality firewall. Here’s how these criteria safeguard the quality journey:

- Deep Dives into Reputation: Investigating a supplier’s reputation, including its history of quality control and customer satisfaction, is crucial.

- Compliance Under the Microscope: Ensuring suppliers adhere to relevant industry regulations and Good Manufacturing Practices (GMP) is essential for maintaining quality standards.

- Certifications as Credentials: Looking for suppliers with relevant certifications, such as those for organic ingredients or specific manufacturing processes, adds another layer of assurance.

- Auditing Beyond the Basics: Going beyond basic paperwork and conducting on-site audits of supplier facilities allows for a firsthand evaluation of their processes and quality control measures.

The Ripple Effect of Quality

The benefits of stringent supplier qualification extend far beyond simply mitigating risks. Here’s how it positively impacts your nutraceuticals:

- Enhanced Product Safety: By selecting reliable suppliers with robust quality control systems, you minimize the risk of contamination or adulteration, leading to safer products.

- Improved Efficacy: Stringent criteria ensure consistent quality in raw materials and processing methods. It results in nutraceuticals that deliver the intended health benefits.

- Building Consumer Trust: Consumers are increasingly discerning. A commitment to quality through rigorous supplier qualification fosters trust and strengthens your brand reputation.

Conclusion

In the competitive nutraceutical market, stringent supplier qualification criteria are not just a nicety; they’re a necessity. By setting high standards for your suppliers, you’re laying the foundation for high-quality nutraceuticals. This translates into safer, more effective products that consumers can trust. Remember, stringent supplier qualification is an investment – an investment in quality, in brand reputation, and, ultimately, in the well-being of your customers. Make it a cornerstone of your nutraceutical business and watch the quality of your products and your brand flourish.