Supplier qualification, the process of evaluating potential vendors, is a crucial step in building a strong and compliant supply chain. But relying on manual checks during this process can leave you exposed to significant risks. In today’s highly regulated environment, failing to ensure supplier compliance can have severe consequences for your business. Here’s why ditching the manual approach for supplier qualification is not just essential, but urgent:

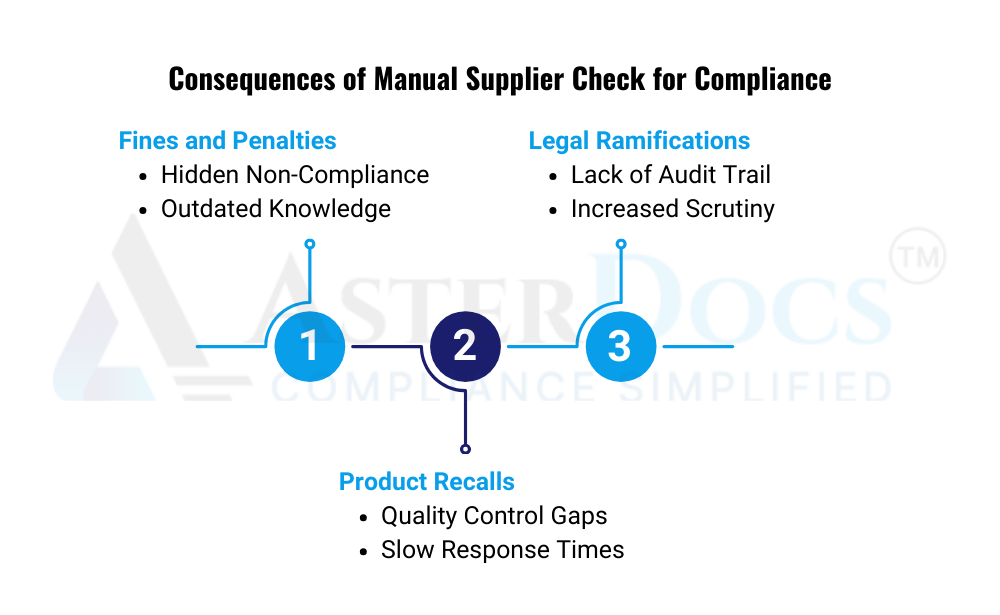

Fines and Penalties

Imagine facing hefty fines for unknowingly working with a non-compliant supplier. This harsh reality awaits companies that rely on manual checks alone. Industry standards and government regulations are constantly evolving, and manual processes can make it challenging to keep track of all the requirements your suppliers need to meet.

- Hidden Non-Compliance: Manual checks might miss crucial compliance details, leaving you vulnerable to penalties for unknowingly partnering with non-compliant suppliers.

- Outdated Knowledge: Keeping up-to-date with regulatory changes can be challenging with manual systems, increasing the risk of non-compliance.

Product Recalls

Picture the devastating impact of a product recall triggered by a supplier’s non-compliance. The potential for product safety issues lurking undetected in your supply chain is a significant risk with manual checks.

- Quality Control Gaps: Manual verification may miss quality control issues in a supplier’s operations, leading to faulty products reaching customers.

- Slow Response Times: Delays in identifying non-compliance due to manual processes can lengthen product recall timelines, further damaging your brand reputation.

Legal Ramifications

In the worst-case scenario, severe compliance violations uncovered by regulatory bodies can even lead to legal action against your company. Don’t gamble with your business’s safety and integrity.

- Lack of Audit Trail: Manual processes often lack a clear audit trail, making it difficult to demonstrate due diligence during legal inquiries.

- Increased Scrutiny: A history of non-compliance can attract stricter regulatory scrutiny, which can significantly burden your resources.

Embrace Automation: The Path to Compliance Confidence

Investing in dedicated supplier qualification software offers a safer and more efficient approach. These tools automate tasks, streamline document management, and provide real-time visibility into supplier compliance. By automating supplier checks, you gain:

- Enhanced Accuracy: Reduce the risk of human error in compliance verification.

- Improved Efficiency: Streamline the qualification process and save valuable time.

- Proactive Monitoring: Identify and address potential compliance risks before they escalate.

Transitioning from manual supplier checks to automation is not just a step; it’s a leap toward building a robust and compliant supply chain. By embracing automation, you can ensure peace of mind, mitigate risks, and shield your business from the costly downsides of non-compliance.