In today’s rapidly growing nutraceutical industry, ensuring the safety and quality of ingredients are paramount. Consumers demand transparency, and regulatory bodies require rigorous tracking of these ingredients. This blog delves into the impact on traceability with supplier qualification software plays in enhancing traceability within the nutraceutical sector. We’ll explore how this technology can bolster the reliability of your ingredient supply chain.

Understanding the Nutraceutical Industry

The nutraceutical industry, which includes dietary supplements, functional foods, and more, operates within a stringent regulatory framework. This framework demands precision in ingredient traceability to meet quality standards and regulatory requirements. To navigate these complex standards and fulfill consumer expectations, businesses in this sector turn to supplier qualification solutions.

The Significance of Traceability

Traceability in the nutraceutical industry refers to the ability to track the origin, production, and distribution of ingredients and finished products. It involves collecting and storing data throughout the supply chain to facilitate quick and accurate identification of an ingredient’s journey.

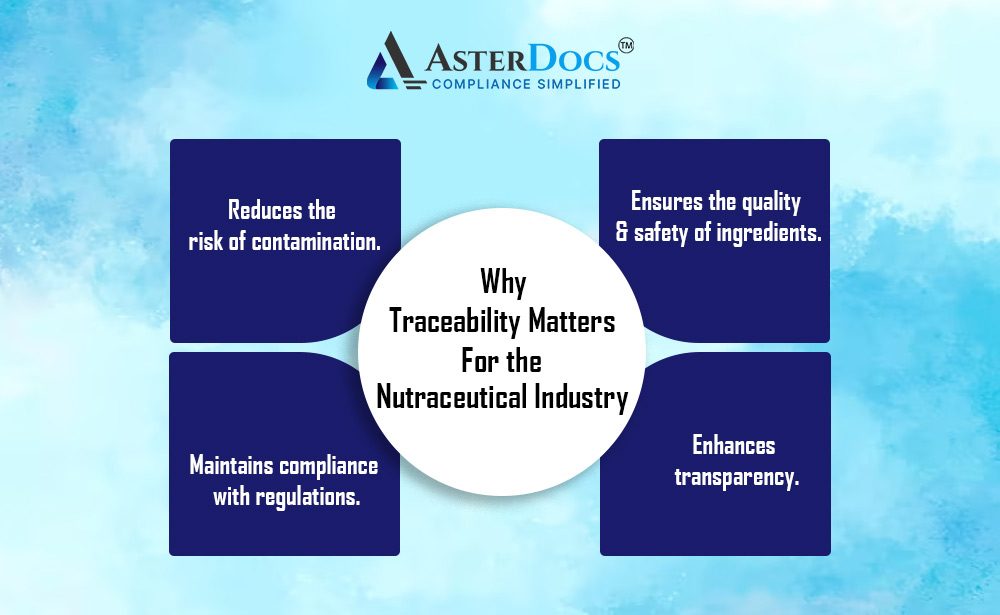

Effective traceability is vital for several reasons:

- Quality Control: In the nutraceutical industry, consumers rely on these products for their health benefits. Any compromise in ingredient quality can be detrimental. Traceability ensures that each ingredient meets the defined quality standards.

- Regulatory Compliance: Regulatory bodies, such as the U.S. Food and Drug Administration (FDA), have specific guidelines for the nutraceutical industry. Failing to meet these standards can result in legal consequences. Proper traceability helps businesses remain compliant.

- Safety: Nutraceutical products must be safe for consumption. Traceability aids in identifying and isolating potential safety issues, such as contaminated ingredients, quickly and efficiently.

Enhancing Documents Traceability

Supplier qualification software is a powerful tool for bolstering documents traceability. It streamlines the collection, management, and sharing of data related to suppliers and their ingredients. Here’s how it contributes to traceability:

- Data Centralization: Supplier qualification system centralizes all data, from supplier profiles to ingredient specifications. This means that all information related to suppliers and their ingredients is stored in one accessible location.

- Data Standardization: Supplier qualification solution encourages consistent data formats and standards. This standardization is essential for ensuring that all parties involved can understand and use the data effectively.

- Visibility and Transparency: The software allows for greater visibility into the supply chain, promoting transparency. Everyone involved in the procurement process can access essential data, enhancing trust and collaboration.

Conclusion

In the nutraceutical industry, ingredient traceability is a crux of product safety, quality, and regulatory compliance. Supplier qualification combined with robust supplier relationship management practices, is the key to achieving and maintaining this traceability. By centralizing data, encouraging transparency these tools enhance the reliability of ingredient supply chains. As the nutraceutical sector continues to expand, the importance of robust traceability systems cannot be overstated.

Businesses that prioritize traceability with software are better positioned to meet demands for safety, quality, and transparency while also ensuring compliance with regulatory standards. The incorporation of supplier qualification software into the procurement process is a strategic investment that pays dividends in terms of product quality, safety, and consumer trust.