Ensuring product quality and sustaining high productivity are critical in the nutraceutical industry. While juggling these two priorities can be difficult at times, businesses can effectively accomplish both with the correct resources. Nutraceutical manufacturers can maintain the highest standards of quality and streamline their operations with the aid of document control software.

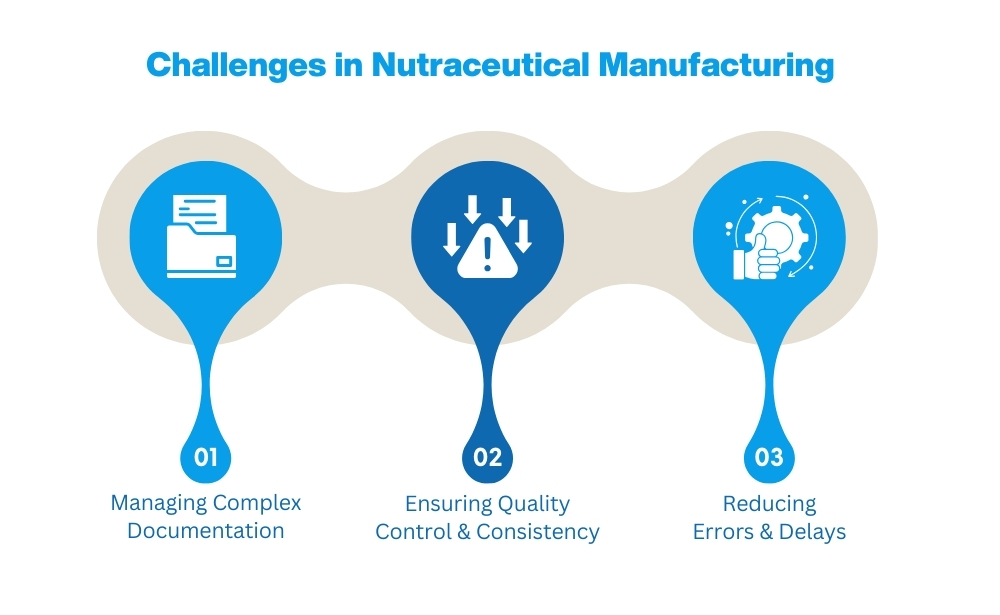

Challenges in Nutraceutical Manufacturing

Nutraceutical manufacturing involves handling complex documentation, ensuring quality control, and minimizing errors and delays. Each of these challenges requires meticulous attention to detail and robust systems to manage effectively.

Managing Complex Documentation

Nutraceutical companies must comply with stringent regulations, necessitating extensive documentation for every aspect of production. Managing these documents manually can be overwhelming, leading to inefficiencies and increased risks of non-compliance. Document control software simplifies this process by organizing documents in a centralized, easily accessible system, reducing the burden on staff and ensuring that all necessary documentation is up-to-date and available when needed.

Ensuring Quality Control and Consistency

Quality control is critical in nutraceutical manufacturing to ensure that products meet regulatory standards and customer expectations. Maintaining consistency across batches is challenging without a system to track and verify every step of the production process. Document control software provides the tools to monitor and document quality control measures, ensuring that every product meets the required standards consistently.

Reducing Errors and Delays

Manual document management is prone to human error, which can lead to significant delays and costly mistakes. Errors in documentation can result in non-compliance, product recalls, and damage to the company’s reputation. Document control software reduces the likelihood of errors by automating many of the documentation processes, providing checks and balances, and ensuring that all documents are accurate and complete.

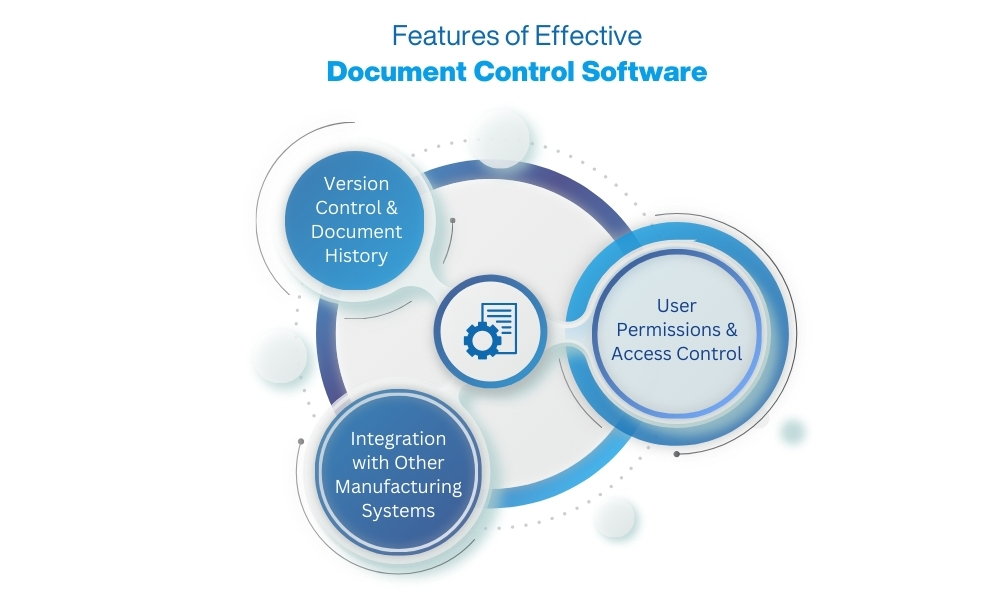

Features of Effective Document Control Software

To address these challenges, effective document control software should offer several key features:

Version Control and Document History

Keeping track of document versions and their histories is essential to ensure that the most current information is always used. Document control software provides version control, allowing users to see the history of changes and access previous versions if needed. This feature helps maintain accuracy and accountability.

User Permissions and Access Control

Not all employees need access to all documents. Effective document control software allows administrators to set user permissions and control access to sensitive information. This ensures that only authorized personnel can view or edit specific documents, enhancing security and reducing the risk of unauthorized changes.

Integration with Other Manufacturing Systems

Document control software should integrate seamlessly with other manufacturing systems, such as Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). This integration enables a more holistic approach to managing production processes, ensuring that all systems work together harmoniously to improve efficiency and quality.

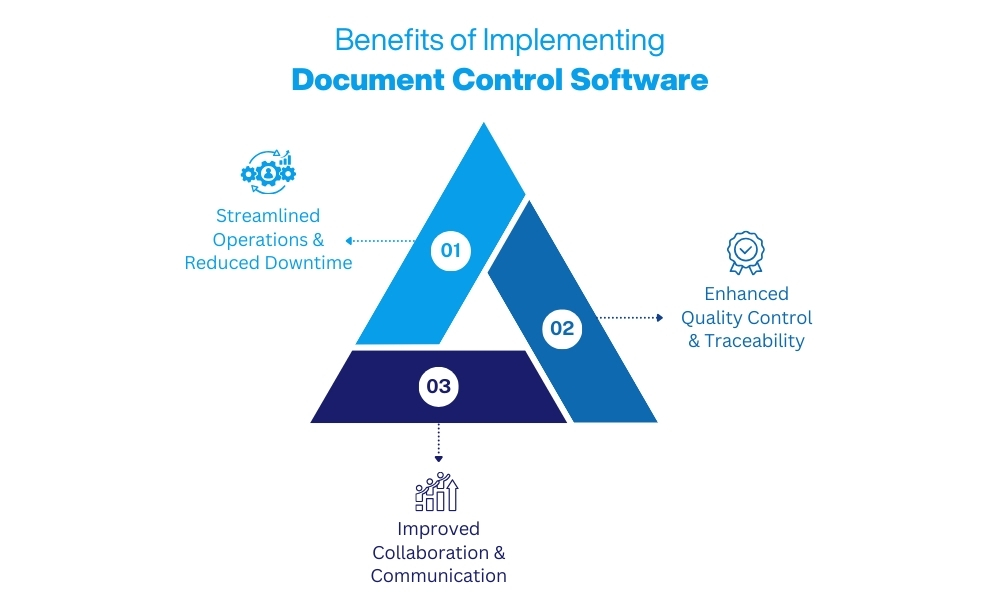

Benefits of Implementing Document Control Software

The implementation of document control software offers numerous benefits to nutraceutical manufacturers:

Streamlined Operations and Reduced Downtime

By automating documentation processes and ensuring that all necessary documents are readily available, document control software helps streamline operations and reduce downtime. This leads to more efficient production cycles and faster time-to-market for products.

Enhanced Quality Control and Traceability

Document control software enhances quality control by providing tools to document and monitor every aspect of the production process. This traceability ensures that any issues can be quickly identified and addressed, maintaining high standards of quality.

Improved Collaboration and Communication

With a centralized document management system, teams can collaborate more effectively, sharing information and updates in real-time. This improved communication leads to better decision-making and more cohesive workflows.

Conclusion

For nutraceutical companies striving to boost productivity and maintain high-quality standards, document control software is an invaluable tool. It simplifies the management of complex documentation, ensures consistent quality control, and reduces errors and delays. By integrating document control software like AsterDocs into their operations, nutraceutical manufacturers can achieve greater efficiency, enhance product quality, and stay competitive in the market.

Nutraceutical companies should explore the benefits of implementing document control software to streamline their operations and ensure the highest standards of quality and compliance.