In today’s complex global marketplace, ensuring the smooth functioning of your supply chain is crucial for business success. However, unforeseen challenges posed by suppliers can disrupt operations, impact customer satisfaction, and even damage your brand reputation. This blog explores common supplier risks and provides effective strategies to mitigate them, ultimately promoting a stronger and more resilient supply chain.

Understanding Supplier Risks:

A well-functioning supply chain is the backbone of many businesses. However, unforeseen issues from suppliers, such as financial instability or quality control lapses, can disrupt production schedules, lead to product shortages, and ultimately, erode customer trust. By proactively identifying and addressing these potential risks, businesses can safeguard their operations and ensure a competitive advantage.

Here are some of the most common supplier risks to be aware of:

-

Financial Instability: A supplier’s financial difficulties or bankruptcy can disrupt production schedules and lead to product shortages. For instance, imagine a scenario where a key component supplier faces financial hardship and ceases operations. This could leave your production line idle and delay deliveries to your customers.

-

Quality Issues: Suppliers who fail to maintain consistent product quality can have a significant impact on your business. Inconsistent quality can lead to product defects, customer returns, and ultimately, damage to your brand reputation. For example, a supplier of subpar materials could force you to recall finished products, incurring significant costs and damaging customer trust.

-

Delivery Delays: Late deliveries from suppliers can throw off your entire production schedule and lead to missed deadlines. For instance, if a raw material supplier experiences delays due to transportation issues, it could cause a domino effect, delaying your production and impacting your ability to fulfill customer orders on time. Reliable on-time deliveries are crucial for maintaining a smooth flow of goods and services throughout your supply chain.

-

Compliance Issues: A supplier’s non-compliance with regulations can expose your business to legal penalties and reputational damage. For example, if a supplier fails to comply with environmental regulations and their practices are exposed, your company could face legal repercussions for being associated with them. Ensuring your suppliers adhere to relevant regulations is not just about legal compliance, but also about upholding ethical sourcing practices and minimizing environmental impact.

-

Cybersecurity Threats: Data breaches or cyberattacks targeting your suppliers can compromise sensitive information and impact your own cybersecurity posture. In today’s interconnected world, a cyberattack on a supplier can easily have cascading effects, compromising your own data security and exposing your customers’ information. Supplier cybersecurity vulnerabilities can create significant risks for your own business, highlighting the importance of collaborating with suppliers who prioritize robust cybersecurity measures.

-

Natural Disasters and Geopolitical Events: Events beyond your control, such as natural disasters or geopolitical instability, can disrupt supplier operations and cause supply chain disruptions. For instance, a flood in a region where you source critical materials could temporarily halt production and force you to find alternative suppliers. While these events are unpredictable, having a risk management plan in place can help you respond effectively and minimize disruptions.

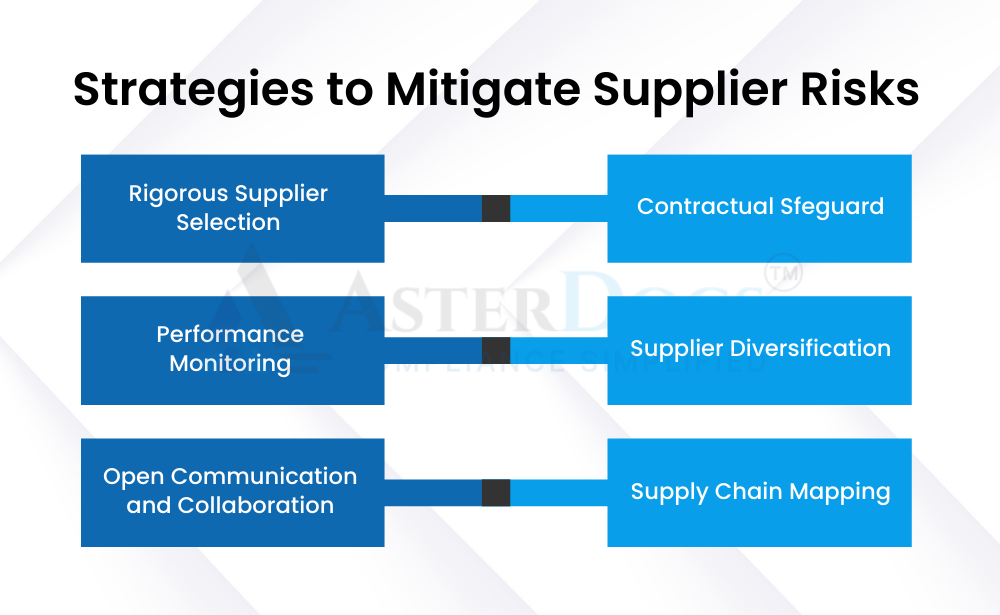

Strategies to Mitigate Supplier Risks:

While supplier risks present challenges, there are established, effective strategies you can take to mitigate them and ensure a more resilient supply chain:

-

Rigorous Supplier Selection: The foundation of managing supplier risk lies in careful selection. Conduct thorough due diligence during the selection process. Evaluate a potential supplier’s financial stability, quality control processes, compliance history, and cybersecurity measures. By partnering with reliable and responsible suppliers, you significantly reduce the risk of future problems.

-

Contractual Safeguards: Establish clear terms and conditions in contracts with your suppliers. These contracts should outline quality standards, delivery timelines, pricing structures, and risk-sharing clauses. Well-defined contracts ensure clear expectations and provide a legal framework for managing potential issues.

-

Performance Monitoring: Don’t just rely on initial due diligence. Regularly monitor supplier performance throughout the relationship. Track metrics like on-time delivery rates, quality control checks, and financial health indicators. By proactively monitoring performance, you can identify potential issues early and take corrective action before they escalate.

-

Supplier Diversification: Avoid dependence on a single supplier for any critical component or material. Develop relationships with multiple qualified suppliers to create a more resilient supply chain. This diversification strategy ensures you have backup options in case one supplier experiences disruptions.

-

Open Communication and Collaboration: Maintain open communication with your suppliers. Foster a collaborative relationship where you can openly discuss challenges and work together to find solutions. Strong communication allows for early problem identification and proactive risk mitigation.

-

Supply Chain Mapping: Gain a comprehensive understanding of your entire supply chain, including supplier locations, dependencies, and potential vulnerabilities. Mapping your supply chain provides valuable insights into potential risk points and allows you to develop targeted mitigation strategies.

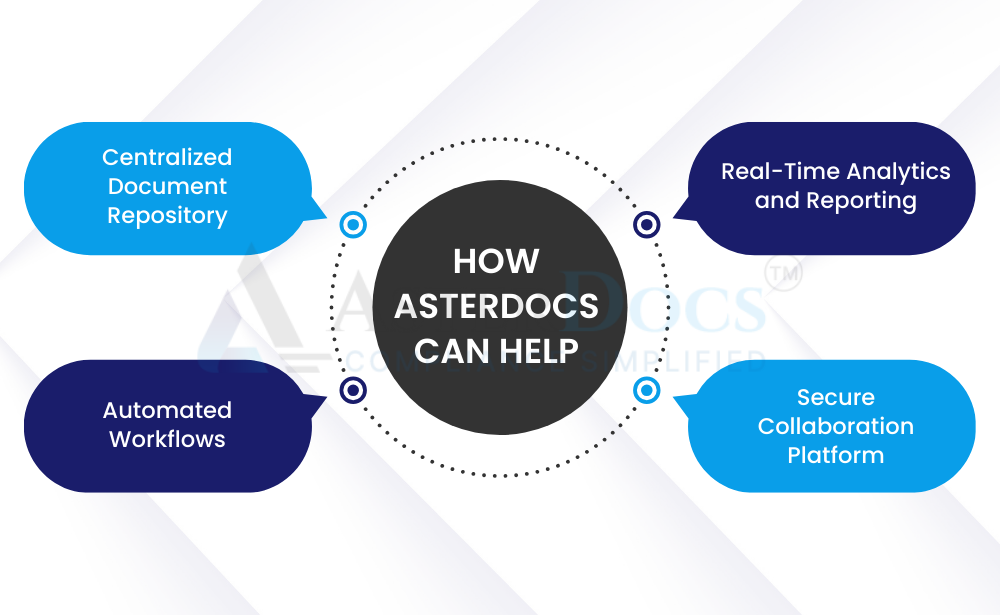

How Asterdocs can Help you:

Managing supplier risk effectively requires a centralized platform to streamline communication, track performance, and maintain vital documentation. Asterdocs empowers you to mitigate supplier risks through the following features:

-

Centralized Document Repository: Store and manage all supplier contracts, performance reports, and risk assessments in a secure, cloud-based platform. This eliminates paper clutter and ensures everyone has access to the latest information.

-

Automated Workflows: Automate tasks like contract renewals, performance metric tracking, and risk assessment reminders. This streamlines processes, reduces manual work, and ensures timely action on critical tasks.

-

Real-Time Analytics and Reporting: Gain valuable insights into supplier performance and identify potential risks with comprehensive dashboards and reports. Asterdocs helps you analyze trends, identify areas for improvement, and make data-driven decisions regarding supplier relationships.

-

Secure Collaboration Platform: Facilitate secure communication and collaboration with your suppliers through Asterdocs’ built-in communication tools. This fosters transparency and allows for early problem identification and resolution.

Conclusion:

By understanding common supplier risks and implementing effective mitigation strategies, businesses can build a more resilient and sustainable supply chain. Asterdocs provides a comprehensive solution to streamline supplier risk management, empowering you to collaborate effectively, track performance, and make informed decisions, fostering a stronger and more resilient supply chain for your business.

Ready to take control of your supplier risk management? Contact Asterdocs today!