Every business knows the value of its suppliers. They’re not just vendors—they’re critical partners in delivering quality and ensuring smooth operations. But what happens when a supplier fails to meet your expectations? The hidden costs of poor supplier performance—delayed shipments, product defects, or compliance issues—can quickly escalate and hurt your bottom line.

This is where supplier scorecard software comes in. By providing actionable insights into supplier performance, it allows businesses to measure, manage, and improve their supplier relationships. Along the way, it also plays a vital role in supply chain risk mitigation. Let’s dive into how supplier scorecards can help save costs and minimize risks while boosting efficiency.

Decoding the Cost Impact of Supplier Relationships

Supplier relationships are complex, and when they falter, the costs can be significant. Here are some of the ways supplier-related inefficiencies eat into budgets:

- Non-Compliance Penalties: Suppliers that fail to meet industry or regulatory standards expose businesses to hefty fines.

- Higher Defect Rates: Poor-quality materials or products result in increased returns, repairs, and wasted resources.

- Delivery Delays: Late shipments disrupt production schedules and can lead to missed sales opportunities.

Without a system to monitor supplier performance, it’s difficult to identify and address these issues proactively. That’s where supplier scorecards shine—they quantify supplier contributions, making it easier to measure and manage their impact on your business.

Supplier Scorecard Software: The Silent Cost Saver

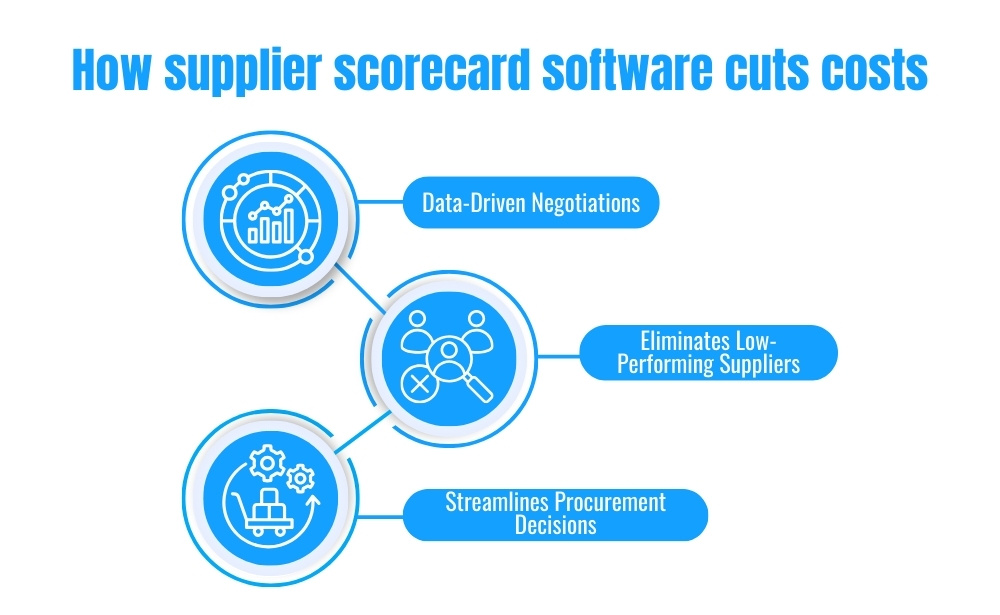

So, how does supplier scorecard software help cut costs? Let’s break it down:

1. Data-Driven Negotiations

Supplier scorecards provide hard data on supplier performance. This allows businesses to renegotiate contracts based on facts rather than assumptions. For example:

- If a supplier consistently delivers on time and meets quality standards, they may be rewarded with larger contracts.

- Conversely, poor-performing suppliers can be asked to lower their rates or improve their service to continue working with your business.

2. Eliminating Low-Performing Suppliers

The software identifies suppliers who repeatedly fail to meet expectations, allowing businesses to phase them out. This not only reduces risks but also ensures resources are allocated to reliable partners.

3. Streamlining Procurement Decisions

Scorecard tools automate supplier evaluations, eliminating time-consuming manual processes. This enables procurement teams to make faster, data-backed decisions that align with business goals.

By improving supplier management, scorecard software minimizes inefficiencies, reduces operational costs, and keeps businesses on track.

Mitigating Supply Chain Risks with Supplier Scorecards

Supply chain risks are inevitable, but the right tools can help businesses prepare for and mitigate them effectively. Here’s how supplier scorecard software aids in risk management:

- Early Risk Identification:

The software tracks key metrics like late deliveries or missing certifications. These red flags allow businesses to intervene before minor issues escalate into major disruptions. - Building Resilience:

Scorecards provide visibility into supplier performance, enabling businesses to create contingency plans. For instance, identifying secondary suppliers for critical components ensures continuity in case of disruptions.

Example: A company using supplier scorecards identified a key supplier frequently missed regulatory deadlines. They proactively worked with the supplier to resolve the issue, avoiding fines and maintaining compliance.

Metrics That Matter: What to Track for Maximum Savings

For supplier scorecards to be effective, they need to focus on the right metrics. Here are some of the most critical ones:

- Delivery Accuracy: Measure whether suppliers meet agreed delivery schedules.

- Defect Rates: Track the percentage of products or materials that fail to meet quality standards.

- Compliance Adherence: Verify that suppliers meet regulatory requirements and possess necessary certifications.

- Cost-Effectiveness: Assess whether suppliers provide value for money without compromising quality.

Focusing on these metrics helps businesses maintain high supplier standards while minimizing risks and expenses.

The ROI of Supplier Scorecard Software

Investing in supplier scorecard software may seem like an added expense, but the return on investment (ROI) often outweighs the initial cost.

Short-Term Wins

- Reduced manual effort in evaluating suppliers.

- Immediate cost savings by addressing inefficiencies like late deliveries or quality issues.

Long-Term Benefits

- Improved supplier relationships that drive consistent value.

- Greater operational flexibility to adapt to market changes or supply chain disruptions.

Case Study: A mid-sized manufacturing company implemented supplier scorecard software to monitor their vendors. Within six months, they reduced late deliveries by 25% and defect rates by 30%, resulting in significant cost savings.

Using Supplier Scorecards to Build Collaborative Partnerships

Supplier scorecards aren’t just about identifying weaknesses—they’re also tools for fostering collaboration. This collaborative approach strengthens supplier relationships while ensuring compliance and cost-effectiveness.

Conclusion

The cost-saving potential of supplier scorecard software lies in its ability to quantify performance, mitigate risks, and foster stronger supplier relationships. By tracking key metrics, automating evaluations, and leveraging actionable insights, businesses can achieve both immediate and long-term financial benefits.

Managing suppliers is no small task, but with the right tools, it becomes a strategic advantage. Ready to take control of your supplier relationships and secure your bottom line? Visit our website to learn more.