Supply chain disruptions can be costly. With global supply chains becoming more complex, businesses are increasingly exposed to risks like operational delays, financial instability, regulatory penalties, and even geopolitical disruptions. This has made supply chain risk mitigation a priority for businesses across industries, particularly in sectors like nutraceuticals, pharmaceuticals, and food manufacturing, where regulations and compliance are paramount.

In this context, supplier risk assessment has emerged as a crucial strategy for managing supply chain risks. By evaluating your suppliers’ reliability, financial stability, and compliance levels, businesses can prevent disruptions before they happen.

Why Supply Chain Risk Mitigation Matters

The complexity of global supply chains exposes businesses to numerous risks. Here’s why mitigating these risks should be a top priority:

- Operational Disruptions: A single breakdown at one link in the supply chain can bring your entire operation to a halt. This includes delays in production, shipment, or even distribution.

- Financial Impact: Any interruption in the supply chain can result in financial losses due to increased operational costs, delayed deliveries, and customer dissatisfaction.

- Compliance Failures: Non-compliance with industry regulations can lead to fines, recalls, and a loss of reputation—particularly critical for the nutraceutical and food industries where compliance is non-negotiable.

Managing these risks requires a strategic approach, where supplier risk assessment plays a significant role.

The Role of Supplier Risk Assessment in Mitigating Supply Chain Risks

Supplier risk assessment helps businesses stay one step ahead of potential disruptions by identifying vulnerabilities in their supplier network. Here’s how:

- Evaluating Supplier Capabilities: Ensuring your suppliers have the capacity to meet demand is essential. Shortages in materials or a lack of resources on their end could impact your operations.

- Financial Stability: Checking your suppliers’ financial health ensures they’re capable of maintaining consistent delivery schedules and withstanding market changes.

- Compliance Monitoring: Regulatory compliance is particularly important in industries like nutraceuticals. Ensuring suppliers adhere to FSMA regulations or provide proper documentation like Certificates of Analysis (COAs) is critical.

By taking a proactive approach to supplier risk assessment, you can ensure that your supply chain remains resilient.

Key Elements of an Effective Supplier Risk Assessment

Supplier risk assessment is multi-faceted. Here are the key areas that every assessment should focus on:

- Financial Health: Suppliers with weak financial standing may be unable to fulfill orders or maintain quality standards. Financial assessments provide early warnings of potential risks.

- Operational Capabilities: Are your suppliers able to scale their operations when necessary? Can they handle an increase in order volume? Assessing their infrastructure is crucial for ensuring consistent supply.

- Regulatory Compliance: It’s not just about getting the job done—it’s about getting it done right. Suppliers must adhere to regulatory standards such as FSMA compliance or ISO certifications to maintain the integrity of the supply chain.

- Supplier Transparency: Trust but verify. Supplier transparency helps you understand the full extent of risks, from raw material sourcing to environmental impacts.

By evaluating these factors, businesses can better anticipate problems before they happen.

Proactive Risk Mitigation Strategies

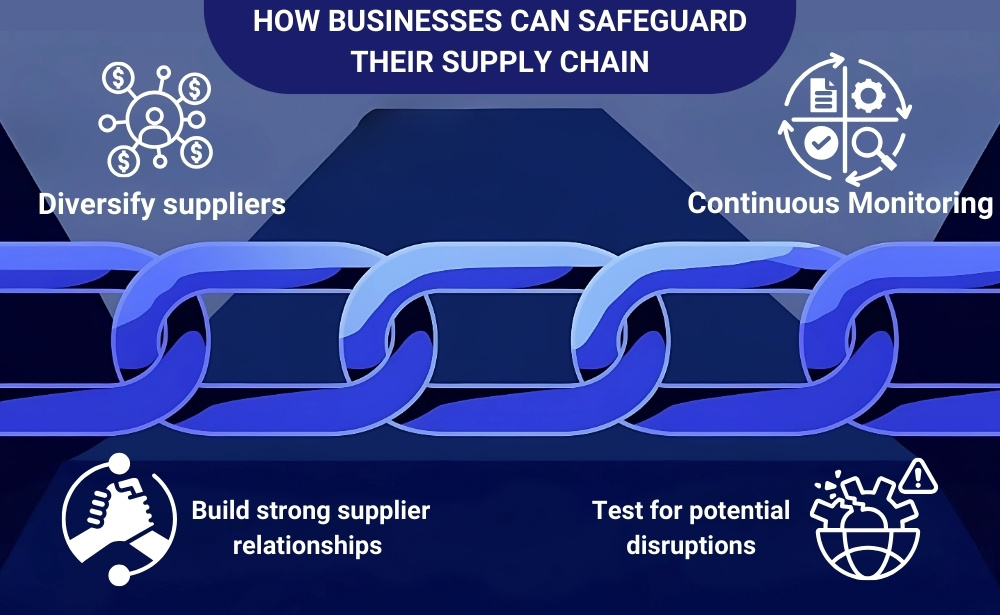

While assessing risks is crucial, taking proactive steps is just as important. Here’s how businesses can safeguard their supply chain:

- Diversification: Relying on a single supplier for a critical product or material is risky. Diversifying your suppliers helps spread the risk across multiple sources.

- Continuous Monitoring: Supplier risk assessment isn’t a one-time process. Use supplier risk monitoring software to continuously assess real-time data and keep track of any changes in a supplier’s performance or risk profile.

- Strong Relationships: Building relationships with suppliers through regular communication ensures that any issues are addressed quickly before they escalate.

- Scenario Planning: Conduct stress tests on your supply chain by simulating potential disruptions. This way, you can create contingency plans for worst-case scenarios.

With these strategies in place, businesses can better prepare for unforeseen disruptions and ensure a steady flow of operations.

Tools for Supplier Risk Assessment and Mitigation

Technology plays a key role in managing supply chain risks. Here’s how the right software can help streamline supplier assessments:

- Compliance Management Software: This ensures that all suppliers meet the required regulatory standards, making it easier for businesses to manage their documentation and stay compliant.

- Supplier Risk Assessment Tools: Platforms equipped with data analytics and AI can automatically monitor suppliers’ financial status, performance metrics, and compliance records in real-time.

Such tools not only provide better visibility into the supply chain but also enable businesses to make data-driven decisions.

Case Study: A Real-World Example

Consider the case of a nutraceutical company that faced supply disruptions because of a lack of supplier compliance with FSMA regulations. After implementing a comprehensive supplier risk assessment tool, the company was able to identify non-compliant suppliers, reduce operational disruptions, and improve overall efficiency.

This demonstrates the power of a proactive approach to supply chain risk mitigation.

Conclusion

In today’s complex supply chain landscape, businesses can’t afford to be reactive. Proactive strategies like supplier risk assessment are essential for supply chain risk mitigation and ensuring a smooth flow of operations. By leveraging tools that offer real-time insights and continuous monitoring, you can protect your supply chain and maintain operational continuity.

To explore how you can streamline your supplier risk assessment and compliance management, visit AsterDocs.